Leeds and Lasers

Leeds and Lasers(a story in three parts with an appendix)

John Offord reports from Leeds Millennium Square

Go to end of story for picture captions

Leeds and Lasers

Leeds and Lasers

(a story in three parts with an appendix)

John Offord reports from Leeds Millennium Square

Go to end of story for picture captions

Leeds’ new Millennium Square, which was officially launched - blizzard-style - on New Year’s Eve, is a new outdoor venue with facilities that many a cosy indoor complex would envy, apart, perhaps, from the absence of a roof. It has a project area of 4500 square metres and a fenceline that encloses 3000 square metres. It has been hailed as one of Europe’ most innovative civic spaces. It can seat 2000 or stand between 5300 and 7000, depending on the configuration. It can be everything from an ice rink to a pop or drama venue. Leeds City Council received £5.4m from the Millennium Commission against a total project cost of £12m and the Square has the equipment and infrastructure to match – from staging and power supply to dressing rooms and crew space. Apart from the technical listing at the end of this piece, here ends part one.

The entire £300,000 contract for production lighting and entertainment laser package for Millennium Square was won by Wakefield-based Futurist. It included the supply of Avolites control and dimming systems, together with Martin MAC 500 and 600 automated fixtures and an entire rig of theatrical lighting, cables and special effects equipment. However, the highlight of the Futurist contract was the supply and installation of eight laser systems, which use new diode technology. They offer Leeds City Centre Management Team a hugely flexible system that can be employed for pure entertainment purposes, projection of advertising for their own events and for income purposes via billboard-style applications, and the ability to use the system for creative expression within a cultural environment. Three control systems have been provided: one to run six lasers (multiplexed together) and two for the stage laser systems.

The entire £300,000 contract for production lighting and entertainment laser package for Millennium Square was won by Wakefield-based Futurist. It included the supply of Avolites control and dimming systems, together with Martin MAC 500 and 600 automated fixtures and an entire rig of theatrical lighting, cables and special effects equipment. However, the highlight of the Futurist contract was the supply and installation of eight laser systems, which use new diode technology. They offer Leeds City Centre Management Team a hugely flexible system that can be employed for pure entertainment purposes, projection of advertising for their own events and for income purposes via billboard-style applications, and the ability to use the system for creative expression within a cultural environment. Three control systems have been provided: one to run six lasers (multiplexed together) and two for the stage laser systems.

Michael Lister, managing director of Futurist, takes up the story. "The equipment, which has been designed by Laser Electronics Limited, uses 2.5W DPSS (Diode Pumped Solid State) technology which has been developed in-house by the company. The lasers are the first of their type to offer full digital blanking capabilities, and a huge factor in their favour is that they do not require three phase power supplier or water cooling. They can simply be plugged into a local 13 Amp domestic supply. They employ an easy-to-use Windows-style operating environment with the control system based on IBM ThinkPad laptop PCs with Laser Electronics’ bespoke Millennium operating software.

"It is the first major major installation of diode laser technology that we are aware of," continued Michael Lister. "In addition, we have already added the new diode lasers - 400mW and 2.5W – to our hire fleet, and they are ideal for corporate presentation work."

Part three will try to take care of the technical development of Laser Electronics’ HPG DPSS laser system, and it’s where Entertainment Technology will do its best to explore the devilling of Clive Davie, the company’ managing director, who has added a spicy mixture into the world of laser development, and who has had experts from the US trekking out to his base in Skegness in an attempt to scoop up some of his skills.

Part three will try to take care of the technical development of Laser Electronics’ HPG DPSS laser system, and it’s where Entertainment Technology will do its best to explore the devilling of Clive Davie, the company’ managing director, who has added a spicy mixture into the world of laser development, and who has had experts from the US trekking out to his base in Skegness in an attempt to scoop up some of his skills.

"In 1997 we decided to invest time and effort into bringing forward diode technology in the same manner as we pioneered low cost laser reprocessing in the early nineties," Clive explained. "Initial development of semiconductor technology dates back to the early fifties and sixties and early laser diode systems were prototyped in the seventies but at sub-zero operating temperatures. Laser diodes eventually became available in the eighties.

"DPSS systems generally suffered from poor reliability, with insufficient thought given to cavity contaminants or external cavity mechanical stress, which resulted in downgraded output and/or failure of SHG (Secondary Harmonic Generation) crystals. There is also the possibility of failure of the primary pump diode, due to high current drive levels. Systems also suffer from poor beam quality and poor divergence. Various systems we tested had similar constraints with side pumping or single in-line cavities, which presented two further problems. One involved the difficulty of thermally stabilising a very narrow cavity made from Alu; as the cavity changes in thermal instability, so does the shape or mode of the beam. The other problem involved the direct modulation of the laser output at moderate to high frequencies of 10Khz and above.

"We solved all of these problems within a relatively short period of time and developed the only UK manufactured 2.5W DPSS laser system that can offer near diffraction limited output @ 2.5W output at 532nm with 10Khz direct modulation and a beam divergence of 0.25mr 1e/2. In short, this allows the laser beam emitted from the output aperture to stay highly focused to produce sharply defined images. Our unit also have a blanking ability so that displayed images can have separate parts within the graphic projection as they use only two high speed galvometer-type scanners to draw images. Most importantly, this means that the perceived output from the laser appears greater than the actual output power."

Our appendix is the story of a new joint venture company that will bring to the market the first UK designed and manufactured diode laser systems to this specification. "As far as we know, it will be the only company to design, manufacture laser light sources, complete diode laser products and control systems," said Michael Lister.

Our appendix is the story of a new joint venture company that will bring to the market the first UK designed and manufactured diode laser systems to this specification. "As far as we know, it will be the only company to design, manufacture laser light sources, complete diode laser products and control systems," said Michael Lister.

And the directors of the new company are, of course, Michael Lister and Clive Davie. Manufacture is expected to commence in March this year and will be undertaken at Futurist’s new site in Wakefield. A demonstration area is planned for June. By then, expect to see a very smart looking, easily portable laser system, with a plug-in-and-go ability. Over 30 orders are already in the sytem, and sales across the first year are expected to reach at least £2m.

Things won’t stop there. By the time the PLASA Show takes place in September, Michael and Clive’s new company also plan to show an automated yoke device with LCD gate technology that uses a laser source rather than a lamp.

Leeds Millennium Square

Main stage:

platform area 14.5m wide x 12.4m deep, with a stage area of 12.4 square metres with a nominal height of 1.5m. The temporary demountable delay towers are able to hold 1000kg each, whilst the temporary demountable front of house position is 4.144 square metres at each of two levels, one at 0.75m and the other at 3.25m.Picture Captions

Millennium Square, Leeds - home for eight new diode technology lasers.

Zeus appears: the graphic frame shown can be produced via the LEL Millennium software in a matter of 60 seconds.

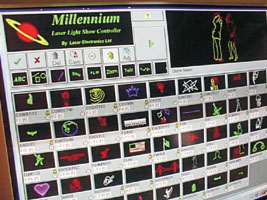

Part of the screen view Graphical User Interface (GUI) for the millennium software system from Laser Electonics

Shark playing a guitar: one of the large number of animations from the Millennium Square library within the Millennium software. The illustration also indicates the brightness produced by the system.

As well as advanced animation, simple effects such as this emulated square can be produced in a matter of seconds.